Digital Twin vs Smart Ship

Ships can face a myriad problem whilst out on sea, including weathering bad storms and facing challenging tides, here a Digital twin can help in decision making. A Digital twin of a vessel is a digital copy, allowing the user to perform simulations and solve problems virtually. It does this by replicating properties as a set of equations, a virtual representation which lasts the life of its counterpart. This enables designers and operators to tackle issues relating to the maintenance and operations of their ships.

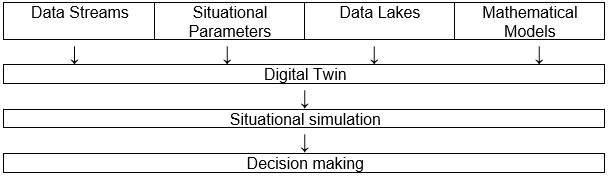

A Digital twin will utilise various methods and machine learning, essentially being the namesake, a twin, to help give current and future predictions. It works in two ways, processing data with advanced hardware and using software to represent and control the acquired data. Possible outcomes are analysed by the digital twin from historical data and real-time current data streams.

Digital Twins are recognised as a useful tool in more than just vessels, it is used in almost anything that involves modelling objects relating to industrial production. The uses of a digital twin range from diagnostics, monitoring and prognostics to optimise asset performance and utilisation. Combining sensory data with historical data, fleet and simulation learning and human expertise improves the outcome of prognostics. And so the root causes of issues and productivity improvement solutions can be determined from complex prognostics and intelligent maintenance system platforms.

Smart Ship

Smart ship is a term for the system that utilises technology and communications for ship operations, maintenance, performance optimisation through a large number of sensors that are distributed to collect as much relevant information as it can. The information gathered is located in system either away from the ship or from the bridge. Smart ship makes decisions based on current readings, not producing any simulations for future predictions, unlike digital twin. For Smart ship to function, and IoT (Internet of things) platform is required for the process, and the data is store using a cloud database, which can be accessed by whomever is making the decision.

To note, Smart Ship is required to have constant bandwidth to work, however is among the growing trends in the maritime industry to become more innovative and smarter.

| Digital Twin | Smart Ship |

| Hardware installation required alongside various software systems | Installation of a lot of sensors, does not require as much software compared to digital twin |

| Factors in external sources, e.g. weather, water characteristics etc | Information gathered from the ship itself |

| Solutions determined from historical data | Real time data, displayed on a dashboard to aid in decision making |

| Less chance of human error due to algorithms and accurate modelling | Uses cloud to gather all data which allows for further study as data is collected |

| Can be used to predict future events and simulations using modern technologies | In comparison to digital twin, more streamlined as no use for historical data between different ship types |

| More costly in comparison to Smart Ship, however more technological meaning more accurate predictions of simulations |